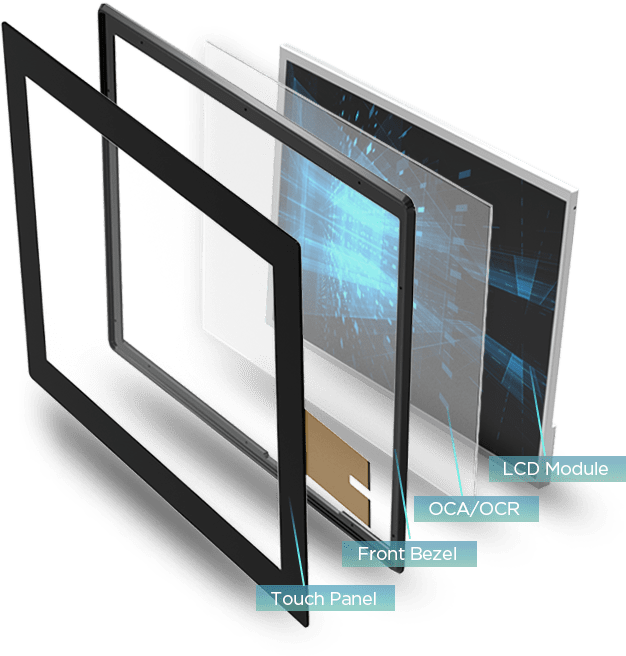

In the realm of touch screen technology, the bonding process is crucial to achieving optimal display performance. OCA (Optically Clear Adhesive) and OCR (Optical Clear Resin) bonding techniques have emerged as industry standards for attaching touch panels to displays. This article explores the significance and benefits of OCA and OCR bonding in capacitive touch screens.

Optically Clear Adhesive (OCA)

OCA is a thin, transparent adhesive layer that bonds the touch panel to the display. It is designed to preserve the display’s visual clarity, ensuring minimal impact on brightness, contrast, and color accuracy. The adhesive properties of OCA keep the layers securely bonded while allowing light to pass through without distortion or interference.

Optical Clear Resin (OCR)

OCR is also utilized for bonding touch panels to displays. Similar to OCA, OCR is a transparent resin material that provides excellent optical properties. It offers superior adhesion, allowing for a secure bond between the layers while maintaining the original visual quality of the display.

Enhanced Display Clarity

OCA and OCR bonding techniques ensure that the touch panel and display maintain their original optical properties. By minimizing the air gap between the layers, these bonding methods eliminate or greatly reduce the occurrence of visual artifacts, such as Newton’s rings, that can affect the viewing experience. This results in a clear and immersive display, allowing users to fully appreciate the quality and details of the content.

Improved Touch Responsiveness

The close bond achieved through OCA and OCR bonding enhances touch sensitivity and accuracy. The reduction in air gap reduces parallax error and increases the precision of touch inputs, resulting in a more seamless and responsive touch experience. Users can enjoy smoother gestures, faster response times, and a more natural interaction with the touch screen.

Durability and Reliability

OCA and OCR bonding provide a robust and durable connection between the touch panel and display. These bonding techniques ensure long-term stability, minimizing the risk of delamination or separation between the layers. The secure bond enhances the overall reliability and longevity of the touch screen.

Technological advancements continue to refine the process of OCA and OCR bonding. Manufacturers are utilizing innovative techniques to achieve thinner adhesive films, reducing the overall profile of the touch screen assembly. Additionally, improvements in adhesive properties and manufacturing processes have led to enhanced bonding reliability and efficiency, contributing to higher-quality touch screens.

OCA and OCR bonding have become integral to capacitive touch screen technology, delivering enhanced display performance and user experiences. Through these bonding techniques, touch panels are seamlessly integrated with displays, preserving their original optical properties while improving touch sensitivity and accuracy. Technological advancements in OCA and OCR bonding have further refined these processes, ensuring durability, reliability, and optimal display quality. As touch screen technology continues to evolve, the integration of OCA and OCR bonding will remain essential in delivering superior display performance for a wide range of applications and industries.

DINGTOUCH is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. However, as a professional touch screen supplier, DINGTOUCH commit to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. Also We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers. However, commit to providing customize solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction. So we have established a good reputation in the touch screen industry and won widespread market recognition.

PCAP maximum size 65”

Multi-touch

Optical bonding service/air bonding

LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

PCAP interface: IIC/USB interface

Also CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

Supports 0.55 mm-12 mm coverslip touch.

Support operating temperature: -40℃-90℃.

We as a professional customized touch screen manufacturer with more than 13 years touch screen experience. So we are welcome to customize your capacitive touch screen . So that here are some of our standard product . Such as 7 inch touch screen, 10.1 inch touch screen ,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,17.3 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen, 23.6 inch touch screen,23.8 inch touch screen,27 inch touch screen.Contact our team today to buy a capacitive touch screen are best for our retail business needs.

our other one website: www.szdingtouch.com