In touchscreen technology, ensuring a seamless connection between the touchscreen (via its flexible printed circuit or FPC) and the main printed circuit board (PCB) is crucial for device functionality and reliability. FPCs must be designed not only for electrical performance but also for mechanical compatibility, particularly in terms of length and flexibility to facilitate the required bending without stress or damage. This article explores how to determine the optimal FPC length and design it for the best bending routes to connect to PCBs.

FPCs are thin, flexible electronic substrates made from materials like polyimide or polyester film. They are used to connect various electronic components, such as a touchscreen to a mainboard, due to their flexibility, which allows for innovative product designs including foldable and curved devices.

Assess the Spatial Requirements:

Evaluate the distance between the touchscreen and the PCB.

Consider any obstacles or components along the path where the FPC will lay.

Account for Bending and Routing:

Design extra length into the FPC to accommodate bends. This prevents tension and potential damage when the device is assembled or during use.

Use 3D modeling tools to simulate the placement and bending of the FPC within the device housing to optimize the length.

Incorporate Service Loops:

Include service loops (extra length loops) in the FPC design. These loops provide slack for easy assembly and potential rework or repairs without stressing the circuit.

Designing FPCs for optimal bending involves understanding the mechanical properties of the materials and the minimum bending radius:

Minimum Bending Radius: Ensure that the bending radius of the FPC is within the manufacturer’s specifications to avoid damaging the copper traces. A general rule is that the bending radius should be at least ten times the thickness of the FPC.

Use Gradual Bends: Sharp bends can stress the material and lead to breakage. Design gradual curves instead of sharp angles.

Stress Relief: Implement stress relief features at bending points, such as strain relief pads or flexible joints.

Secure Attachment:

Use high-quality connectors that match the specifications of both the FPC and PCB. Ensure that the connectors are capable of sustaining the mechanical load during flexing.

Consider the use of ZIF (Zero Insertion Force) connectors, which are ideal for FPCs because they reduce mechanical stress during insertion and removal.

Testing and Prototyping:

Always prototype the design before final production. This helps identify any practical issues with the FPC length or bending paths.

Conduct functional and stress tests to ensure that the FPC maintains connectivity and performance throughout its operational life.

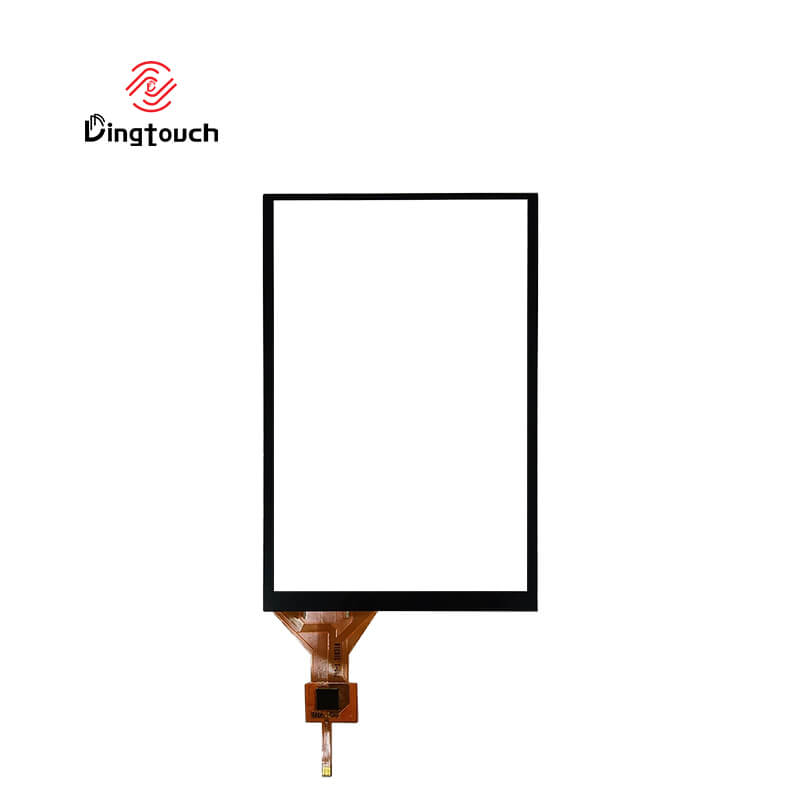

DINGTOUCH is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. However, as a professional touch screen supplier, DINGTOUCH commit to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. Also We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers. However, commit to providing customize solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction. So we have established a good reputation in the touch screen industry and won widespread market recognition.

PCAP maximum size 65”

Multi-touch

Optical bonding service/air bonding

LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

PCAP interface: IIC/USB interface

Also CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

Supports 0.55 mm-12 mm coverslip touch.

Support operating temperature: -40℃-90℃.

We as a professional customized touch screen manufacturer with more than 13 years touch screen experience. So we are welcome to customize your capacitive touch screen . So that here are some of our standard product . Such as 7 inch touch screen, 10.1 inch touch screen ,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,17.3 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen, 23.6 inch touch screen,23.8 inch touch screen,27 inch touch screen.Contact our team today to buy a capacitive touch screen are best for our retail business needs.

our other one website: www.szdingtouch.com